In our testing of the impact of strong solvents on the reproducibility of runs on analytical HPLC silica columns[1] we found a significant amount of wash is required for the column to behave as it did prior to first running a strong solvent on it. Surprised by how much solvent was needed, a conversation began among those of us in the Applications lab regarding this same effect on flash silica columns and the true cost of trying to reuse them.

The idea behind the reuse of flash silica columns is naturally to save money by purchasing fewer columns, and possibly reducing the cost of solid waste disposal. Well, if only it were that simple, that would be the end of it! But to properly evaluate a column-reuse strategy, the cost of several measures that must be taken in order to restore the column's performance must also be considered, as follows:

One significant problem is swelling and how to prevent it. Flash column bodies will swell over time when left in contact with solvents such as hexanes, ethyl acetate, DCM, and others commonly used in normal phase flash chromatography. As the column swells, channels begin to form within the silica packing, allowing mobile phase and sample to bypass the stationary phase. To prevent swelling, users will flush the column with 2-propanol as a way to remove as much of the retained strong solvent as possible and to also act as a storage solvent. Flushing with 2-propanol is one of several suggested protocols for storage of our reusable, functionalized stationary phases such as RediSep C18, Gold C18, Gold C18Aq, Gold C8, and Gold Amine columns. In any case, the cost of flushing must be taken into account.

Another significant problem is column performance (retention time). A loss of retention in a reused column occurs when silica surface activity is reduced by impurities that 2-propanol cannot remove. This results in the used column running as if it were a shorter one. Method development with a used flash column also becomes more difficult, since the change in retention time means it will no longer match with TLC plates.

Another significant problem is column performance (retention time). A loss of retention in a reused column occurs when silica surface activity is reduced by impurities that 2-propanol cannot remove. This results in the used column running as if it were a shorter one. Method development with a used flash column also becomes more difficult, since the change in retention time means it will no longer match with TLC plates.

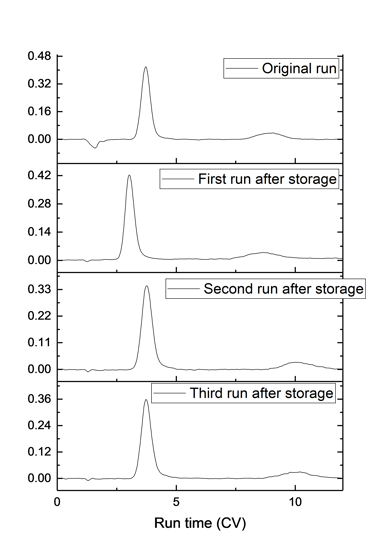

The chemistry of a flash silica column is no different than that of an HPLC silica column, and so running the flash silica column with a strong solvent has the same effect as using a strong solvent in an HPLC column. That is, it takes a long time and a significant amount of wash solvent to make the column perform as it did prior to running with the strong solvent. This phenomenon is clearly reflected in the runs depicted in the chromatograms below, where a new flash column was used for a purification, and was then stored in 2-propanol for several hours. The used column subsequently required three runs before the first eluting peak had the same retention time as the original run.

Top run was on a new column, which was washed with 2-propanol. Subsequent runs used the same method as the original run. The second peak never totally eluted as it had when the column was new. The com pounds are acetophenone and 4'-methoxyacetophenone run in 10% ethyl acetate in hexanes.

Having established the amount of solvent required to restore a flash silica column to its original state, we can now evaluate the cost of reusing the column versus buying a new one.

The table below lists the costs of the solvents needed a) to wash the prior eluting solvents before storing the column, and b) to restore the column's performance in terms of consistent elution of target compounds.

| Cost of Solvents Required to Maintain Flash Column Performance | ||||||

| Solvent | Part Number and Quality (Grade) | Purchase Volume (mL/bottle) |

Price Per Bottle (USD) |

Price/mL (USD) | Volume Needed (mL) |

Flash Column Maintenance Cost (USD) |

| 2-propanol | A516-4, USP grade | 4000 | $275.00 | $0.069 | 150 | $10.35 |

| Pet ether | Tech grade N3S-4 | 4000 | $79.50 | $0.020 | 1800 | $36.00 |

| EtOAc | Tech grade 18-610-403 | 4000 | $205.92 | $0.051 | 200 | $10.20 |

| Total cost of solvents: | | | | | | $56.55 |

| Price of a new flash column: | | | | | | $19.27 |

| Net gained (or lost) by reusing the column: | | | | | | ($37.28) |

In this evaluation, the total cost of the solvents required to store the column and re-establish a consistent retention time is $56.55, as compared to $19.27 for a new column, for a net loss of ($37.12).

Notes:

- All prices shown are list, no discounts, sourced from VWR or Teledyne ISCO; prices obtained 15 March, 2021.

- Cost of solid waste disposal when purchasing a new column is not included in the evaluation.

- Cost of liquid waste disposal for the additional solvents consumed when reusing a flash column is also not included.

- The above evaluation is based on using petroleum ether, which is far less expensive than hexane.

- Using technical grade hexane instead at $226 per 4 L bottle would have cost $102.60 per column, making the total cost of solvents $123.15, for a much higher net loss of ($103.88) per column.

As can be seen from the analysis, it costs far more to reuse a flash column than to buy a new column. And with a new column there is no risk to the accuracy of method development and scale up.

We hope this data is useful in justifying the purchase of new columns when needed. We would love to hear any questions or comments about these calculations, and any further tips or tricks you might have regarding the pros and cons of reusing flash columns.

For more information on TLC or our Chromatography products, visit https://www.teledyneisco.com/chromatography or contact us